Engine dimensions scratchpad (my own reference, might as well keep it here).

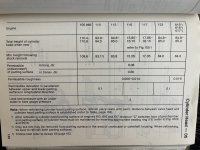

Iron 116 92x65.8

Alloy 117 96.5, 98.5/99 practical bore limit

116 CR 138+--.05 CH 43.15 *

117 154.5+-.05, 48.1

116.985 piston rings are 1.75 and 2.5 thick, with a 4mm oil ring. Compare je for na typical of aftermarket us v8s with 1 and 1.2 with 2.8 oil, or 1.2 and 1.5 in boosted applications.

All except alloy emission markets (AU, JP, US) BE 52, pin 26

Emission 48, 23

bah. journal sizes. rod BE bores are actually 55.6 and 51.6. Rod journals are 50mm wide, allow for 3mm fillet (2mm is acceptable).

Alloy CCccs:

7 56+-.5

6 45+-.5

Iron

7 45

Decks alu

6 216

7 245

*note if this is true 6 Iron block is 213 given tech data in manual, 32.9+138+43.15=214.05

Only 26 gudgeon I found was for a 1.9tdi

Nissan oilers up to 30

Most benziner 23 or less. Ls1 .945", m5x are 23 iirc, but s52 21. All Rb are 21. Honda b18 and k20 are 138,139 CR and 51 BE. 21 and 23 gudgeon resp. Rev limiter.

92 is ej20, 99.5 is ej25. BE 55 but gudgeon 23. Need only match gudgeon and CH. Rods are short tho.

Modular 4.6 2v 3.701" je 314572 -11.6cc 31CH 350g but offset pin

(If na 1,1.2 rings, pc 1.2, 1.5) rings from total seal, clips (#866-063-MW), pins #866-2250-15-51C (98g).

Also a 3.622" option 314664 but -30.5cc and 33.53 CH.

314571 is 3.622" 2v -9.3cc 1.2" CH 345g

2j matches BE with 5.590" CR eg SCAT SC2559020471020 mostly 1.02" wide

Looks like -8mm deck height with 572 so can go 7 Iron crank and mill 1.75 off the pistons. Bit much.

Gives 4.7L, ratio 1.67, 635(callies)+100+350=1085 total, 10.7:1.

callies rods have a 25mm pin end width for all sbc/ls/sbf

consider a 5.7" large journal (2.1") sbc rod with clevite CB-745p-40 (40 thou undersize) bearings should give 52.324mm plus clearance, or better an oversize small journal one if possible (2.04"=51.816 ~ halfway between new and 1st repair stage 6/7 crank spec... assume .002 clearance so actually 51.866...)-bah, no such thing. only 0.001 oversizes for extra oil clearance etc. 2.225"=56.515 is the standard 2.1 journal BE bore, so probs best off just using mercedes spec bearings and honing rods by 0.095mm diameter... LOL: callies list journal size, so supra rods are probably fine...

6/7 rod bearing is 22mm face, supra is 19mm, acl 4B2166H (ford/cosworth yb) is 20.xx and BE dimensions matches the supra. Remember: rod bearing to suit the rod (given a journal match).

Looks like iron/euro alloy crank+yb bearing+supra rod+modular 2v piston. Face the big ends down to 24.bla 6/7 width. Select piston to get compression height close as possible with crank/rod combo and possibly machine some rim off the bowl. Valve reliefs are probably fine untouched as modular has more lift. Can also use 1uz rods (144 vs 142 for supra). BE and tolerances should/seem to be the same. May be narrower. Yes they are, .907" vs 1.02". They're 146 long though...

Concerns

Piston speed. Original 6 design had short stroke to limit speed to 14.2m/s @6500

Coyote has 92.7 stroke and 7000rpm gives 21.63m/s so can probably go 7500 on 7 crank (21.25m/s) purely from a piston speed perspective... oil cav another matter... at least 6500 should be OK, from journal size too.

Journal widths. Supra aftermarket gudgeon is 1", BE 1.02". Modular is .94" all round but have also seen .965 PE. 7 is 22mm - bah,must be alloy (or wrong): 24.87 in 03-313! - 22 is the seat width - PE is 27.95. see journal dimensions above, modular would be fine. can also use chamfered bearings like Scat recommends for cranks with beefy fillets. They literally mount a stock bearing to a dummy rod and machine it on a mill.

Air. The big one. Need manifold mod. Stock port velocity is 280ft/s according to AutoCar article (38mm runner diameter used) - suggests 280/2.4=116(lol)x1.758"^2[APA]=204CFM max flow. Similar to generic yank donk at 7.62mm lift. Ideal is ~350ft/s for proper swirl, but how best to get there given any mods...

Balance. New crank. Could be halving moving mass... but include rockers! Bmw roller followers from n42?

Spring harmonics if recline increase.

Back cut valves or replace for mass red. Modular 2V are 44.5mm, stock 116 is 44mm

64mm main. Modular 67.xxx. 2j 62. Speed/main journal seems OK. Rods also come in 48/47.95 "honda" BE size to suit a chev 1663H bearing, might fit an emissions alloy crank? Better for revs eh. consider journal overlap for crank stiffness. ROT says .2" minimum. Makes 32mm the minimum rod journal size on a 7 crank...

... should be fine...